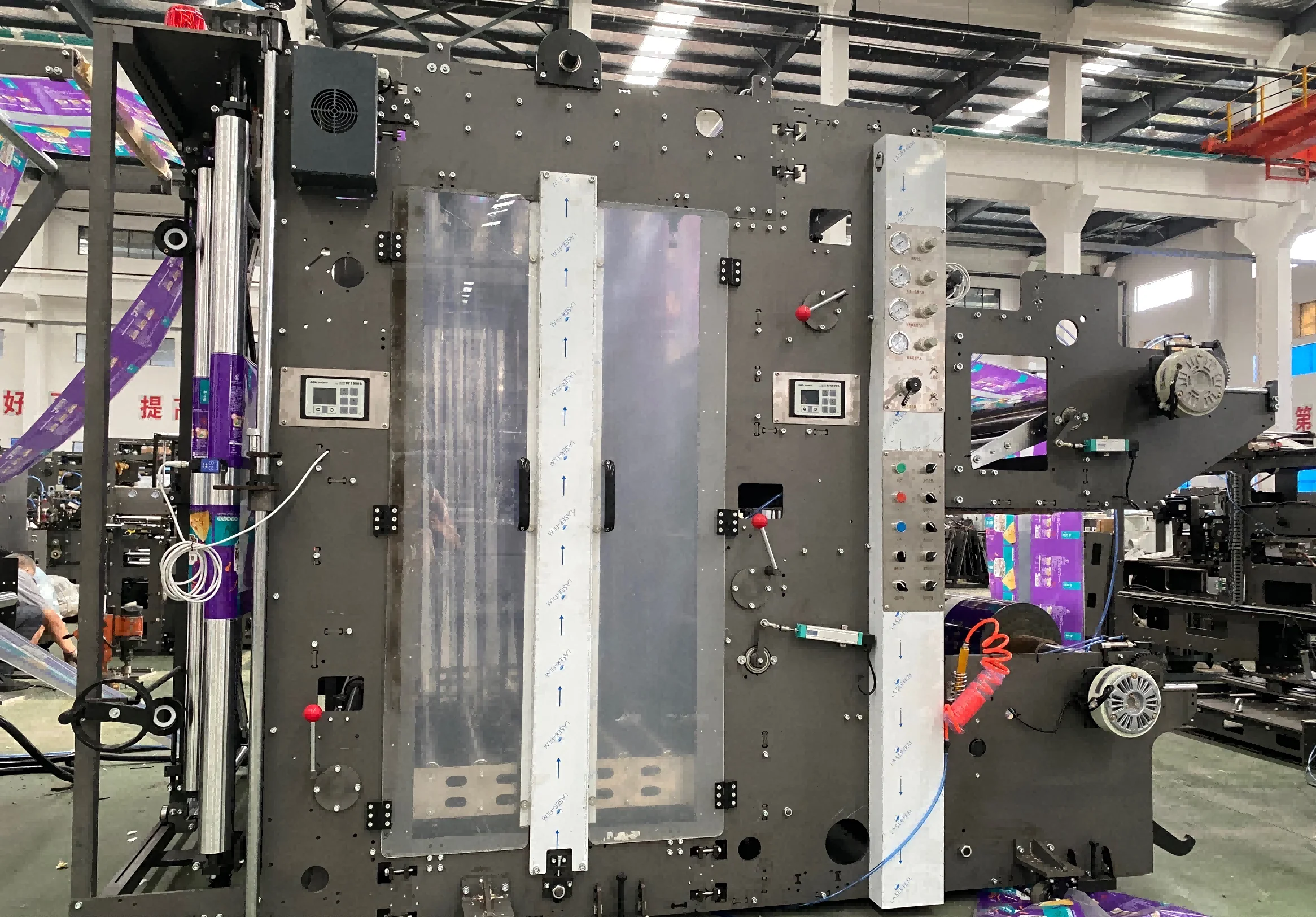

Automatic Flat Bottom 8 Sides Sealing Pouch Bag Making Machine WSD-800F

- 8 Sides Sealing

- Flat bottom

- Zipper bag

- Professional Bag Making Machine Manufacturer

Description

Application:

WSD-800F Flat Bottom 8 Sides Sealing Pouch Bag Making Machine combines light, electricity, air together, driven by servo motors. It is a high quality , high speed and suit for laminated film bags.

Suitable Range:

1.Material: BOPP, OPP, PET, PA and other laminated film, multi-layer coextrusion film, Al foil, aluminized film, paper laminated film and so on.

2.Machine Type: 3 side seal, Zip, Flat bottom pouch , 5 feeding units (Main servo motor)

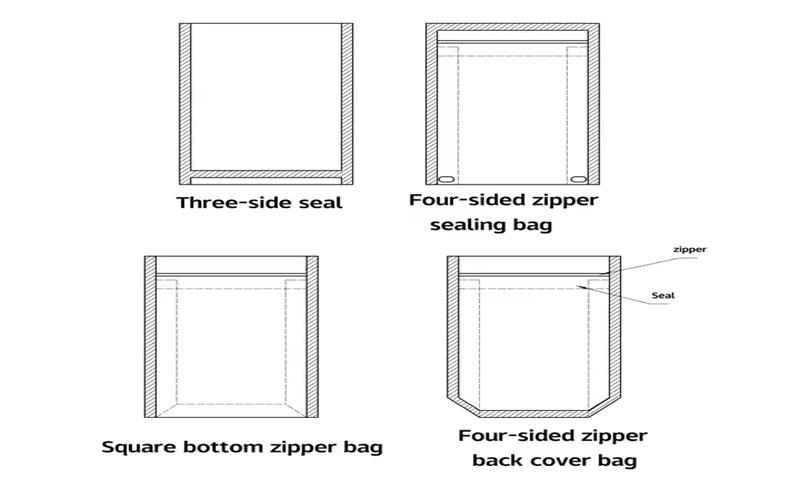

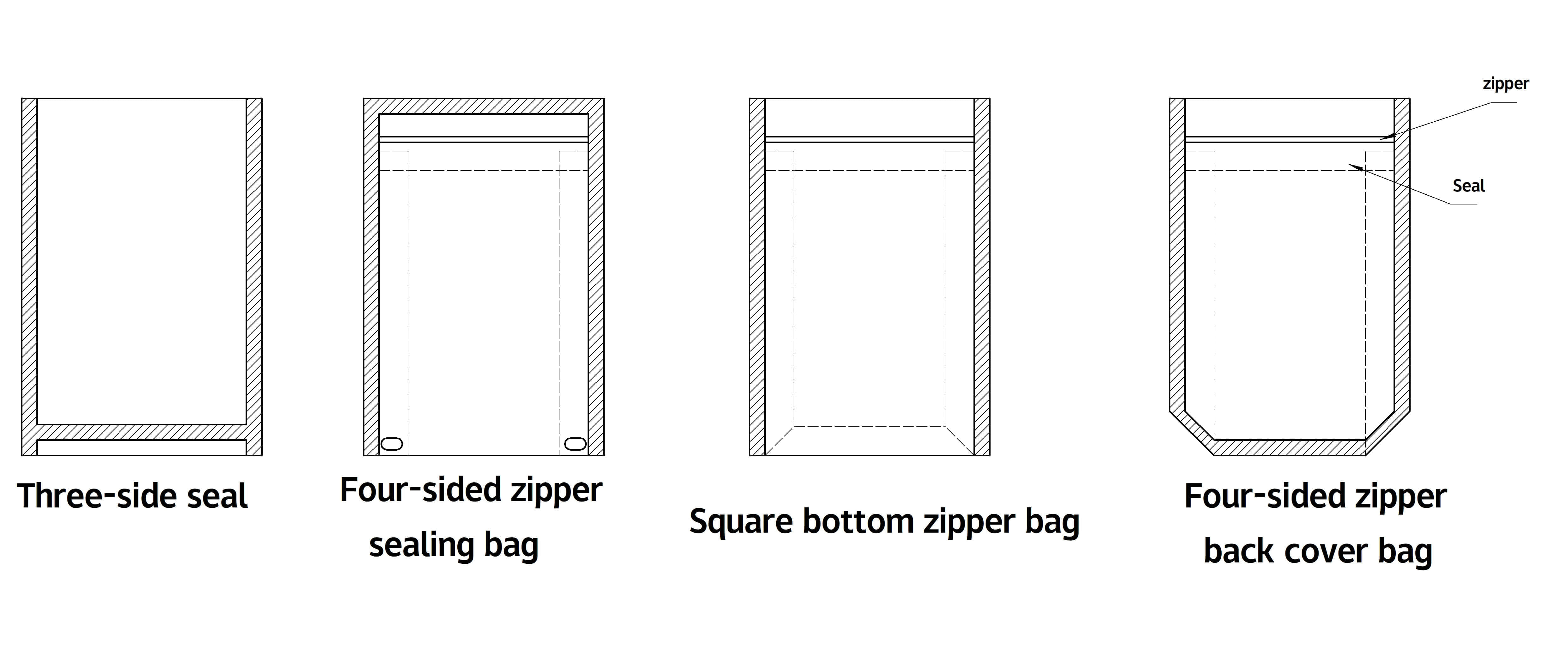

3.Pouch Kinds:

4.Material Roll: Max width: 1300mm; Max dia.:800mm

Machine Technical Data:

1.Machine Speed:

1) 3 side seal:80-120 cut/min;

2) One line flat bottom pouch speed:80 cut/min;

3) One line flat bottom with zip pouch speed:80cut/min;

2.Pouch width:

3.Pouch Length:

You can set the pouch length when bag length more than 300mm less than 500mm;

Unwind Type:

2.Add the material storing structure which is used to achieve to splice without stopping the machine. When up unwinder is working, down unwinder can prepare the material roll.

Drive type:

2.Seal Unit: AC servo motor controls.

Operating Function:

1.Hot Sealing: Sealing Speed.

11.Message:

a. photoelectric lost;

b. report the loss of temperature;

c. to alarm;

d. the servo motor alarm;

e. tension alarm and automatically stop.

14.Machine Dimension(L*W*H):26000*3500*1932mm.

15.Equipment overall weight: about 12.8 t.

Unwinding unit:

1.Unwind Structure: Unwind uses air expand shaft, locked by pneumatic parts.

2.Unwind Parameter: Unwind dia≤Φ800mm. Width≤1300mm.

3.Unwind tension is controlled by magnetic brake and roller type encoder. And there are also dance roller and protection device of film break.

4.Unwind Feeding Motor: Unwind feeding device is synchronous with main speed( Motor 0.55kw+0.75kw inverter) to feed the material.EPC control with photocell.

5.Material Roll Unwind Structure: Adjust screw to adjust up & down material. Dance structure to adjust the tension.

8.Unwind Splice without stopping machine: There is material storing frame, it can take 35 meters in store. This frame can ensure that achieve splicing in limited time.

Longitudinal Sealing Device:

Drive: Main motor drives eccentric link to do vertical movement.

Heat Power:2.5KW

Length:800mm, Cooling 480mm

1.Structure: Longitudinal heating bars combined cooling bars with sprint press structure. The heating frame moves down when stopping the machine, and resets when restart to work.

2.Drive: Main motor drives eccentric link to do vertical movement.

3.Heat Power:2.5KW.

4.Qty.: Heat Seal 3sets, Cooling Seal 3sets.

5.Length 800mm, Cooling 480mm.

Transverse Heating Unit (6 sets Heat Seal, 2sets Cooling)

Structure: Transverse heating bars press with spring structure.

Drive: Main motor drives eccentric link to do vertical movement.Pressure: Standard pressure 1000kg, Max. pressure 1500kg.

Qty.: Heat seal 4sets, Cooling seal 2sets.

Heat Power:2.5KW.Length:880mm.

Structure:Transverse heating bars press with spring structure.

Drive: Main motor drives eccentric link to do vertical movement.

Quantities: 2sets.

Ultrasonic device:Chinese good brand ultrasonic device,Two sets.

Side Gusset, Angle Shape, Positioning Sealing

(2)Side Gusset Fold Cutting Blade: 0.75KW Panasonic servo motor +APEX servo reducer to control the cutting blade.

(3)Side Gusset Unwind (Two Units): Unwind is 200W reduce motor. Unwind brake is 0.6kg to ensure the permanent tension. EPC control device one set(Two sensors), photocell detects the signal and reflect to the controller and drives the reduce motor to adjust the web position.(4)Side Gusset Pre-heat: Heat plate 3sets, 6 routes.

(5)After cutting the side gusset, use the air cylinder suck the gusset film and servo motor controls to move the gusset film with timing belt. Fix the length using servo motor, and heat press at the same time.

(6)10 inch Taiwan touch screen.(7)Gusset unwinder can be spliced without stopping the machine.

Film Feeding Device

Drive: Panasonic servo motor to drive the rubber roller, 5 feeding motors: Front feeding servo motor 1.5KW, middle feeding motor 1.5 KW, back two motors are 1.5KW. Unwind tension feeding is 1.5KW servo motor.

(2)Transmission: Timing belt.Control mode: Computer central controls same step and tension.

Tension In The Middle

(2)Control Mode: Computer central controls.

(3)Control mechanism: Dancer roller structure compensates the web step length .(1)(NPN)Detection mode: Approach switch.

(2) Tension range: 0.1-0.2mm (Computer sets, compensate each other)

(1)Structure: Crank rocker push-pull type connecting rod structure.

(2)(4KW)Drive: Panasonic servo motor.

(3)Transmission: Transmit with timing belt equipped with 1:10 servo reducer.(4)Control mode: Computer central controls.

(5)Moving mode: Main motor takes the whole frame to do the vertical movement.Auto Positioning Device

(1)Detection way: Reflection type photoelectric sensor tracking detection.

(2)Accuracy: 0.01~0.25mm.(3)Integrated positioning accuracy:0.5-1mm.

(4)Sensor tracking scope: ±9mm.(5)Sensor compensating scope: ±9mm.

(6)Positioning correct way: Servo tracks the current compensation with auto matic displacement correction system.

Temperature Control Device

(2)Control mode: Computer central controls, PID adjustment, Solid relay driving.

(3)Temperature setting scope: environmental temperature~360℃.(4)Detection point: Middle in the heating bar.

Cutting Knife

Structure: Up knife+ adjusting device+ fixed down knife.

Type: Spring shear knife.

Transmission: Servo motor drives, eccentric frame do vertical movement.

Adjustment: Transverse movement(two sides)

Working Principle

(1) Firstly starting the machine, the second clamping device move the material to the right position and cut one time. Then the main material unwinder pass through the tension structure and separate to two sheets.

(2)After that, it goes into the recycle. When the main material is at the right position, Panasonic servo motor takes the bottom material to the target position. At the same time, bottom material enters and press.

(3)After pressing, the bottom film is sealed with main film. And then, servo motor controls to return. After sealing, the sealing motor returns and the bottom film feeding motor finishes. The second cutting cut the bottom film and returns. After all above actions, one cycle action finishes.

Other Component

(1) PE Unwind Device 2set, Down sealing knife lift structure. Heating length:800mm Cooling:480mm.

(2) Unwind Type: K shape unwind structure.

(3) Transverse Punching Device: Puncher Frame 2 sets, Round corner puncher 2sets; Rhombus puncher 2*4mm 2sets.

(4) Slitting Device: Adjust the slitting knives by manual, and fine tuning by screw shaft.

(5) Working Platform: Movable working desk. The convey belt is controlled by reduce motor. Touch screen set the conveying number.

(6) Trim Rewinder: 2sets.

Supplies (Customer Supply)

(1) Power: 3P 380V±10%, 50Hz.

(2) Compress Air: 0.6Mpa.

(3) Cooling Water: About 15L/min.Remarks: This machine is multi-layer high quality function bag making machine. It has high requirements for printing error±0.15mm;The stretch after printing, laminating and slitting should be minimum, or the cumulative error will cause the waste.