Medical Bag Making Machine With Medical Sterilization Center Paper Strip Pouches MJ-350-C

- With Central or side Dialysis Paper Strip

- China Machine Original Design Factory

Description

center strip pouches medical sterilization paper and film packaging central sealing medical bag making machine

(double servo type)

Application:

This machine is special designed to make medical bag with easy tear off paper strip ,also suitable for cutting all kinds of food packaging, Coffee packing,candy packaging, big cake bags, stickers, coated paper bags, etc.

Performance and characteristics:

The Middle and Bottom Sealing Bag Making Machine is designed for high-efficiency sealing and cutting of flexible Medical packaging composite bags. Ideal for automated middle sealing, bottom sealing, and precision cutting, this machine enhances production efficiency and packaging quality.

Key Features:

✅ Advanced Control System – Microcomputer automatic control with servo motor and variable frequency speed regulation for precise operation.

✅ High-Precision Photoelectric Tracking – Ensures accurate positioning for flawless sealing and cutting.

✅ Smart Temperature Control – Maintains stable heating for firm and smooth sealing.

✅ Four Hot Sealing Stations – Enhances seal strength and durability for various flexible packaging materials.

✅ Customizable Add-ons – Options to include punching dies, tear notches, and single-film bag sealing to meet diverse packaging needs.

✅ High-Speed & Stable Operation – Ensures consistent output, minimal downtime, and optimal productivity.

This high-performance packaging machine is widely used in food packaging, pharmaceutical packaging, and industrial packaging, ensuring cost-effective and reliable sealing solutions.

Would you like further refinements for your target audience? 😊

Machine Configuration

| Mechanical part | Electrical part |

1. Unwinding device: the unwinding device adopts magnetic powder and air shaft | 1. Unwinding magnetic powder 2.5KG (china brand) |

2. Frame: adopt steel plate structure | 2. Double servo motor control 2KW 2sets |

3. Cross-cutting tool holder: adopts casting structure | 3. Double photoelectric tracking and positioning device for edge correction machine (Zhejiang Julong) |

4. Cross-cutting knife: using domestic ordinary cutting knife | 4. Independent microcomputer control cabinet: automatic counting, automatic alarm when the number is reached. Automatic shutdown function for lack of material |

5. Drive shaft: rubber shaft slotted | 5. Traction adopts variable frequency motor speed regulation (Shanghai) |

6. Hot knife: The bottom seal adopts aluminum structure (2 two horizontal ironing, 1 cooling.) The middle sealing hot knife adopts a longitudinal ironing knife, and 1 longitudinal cooling and flat pressing. | 6. Computer touch screen control (PLC) |

7. Feeding traction mode: motor drives belt pulley to drive traction rubber shaft | 7. Main engine adopts 2.2KW motor (Shanghai) |

8.Max material width 700mm max bag width 330mm | 8. working speed 120 bags/min |

| 9. Whole machine weight 1500kg | |

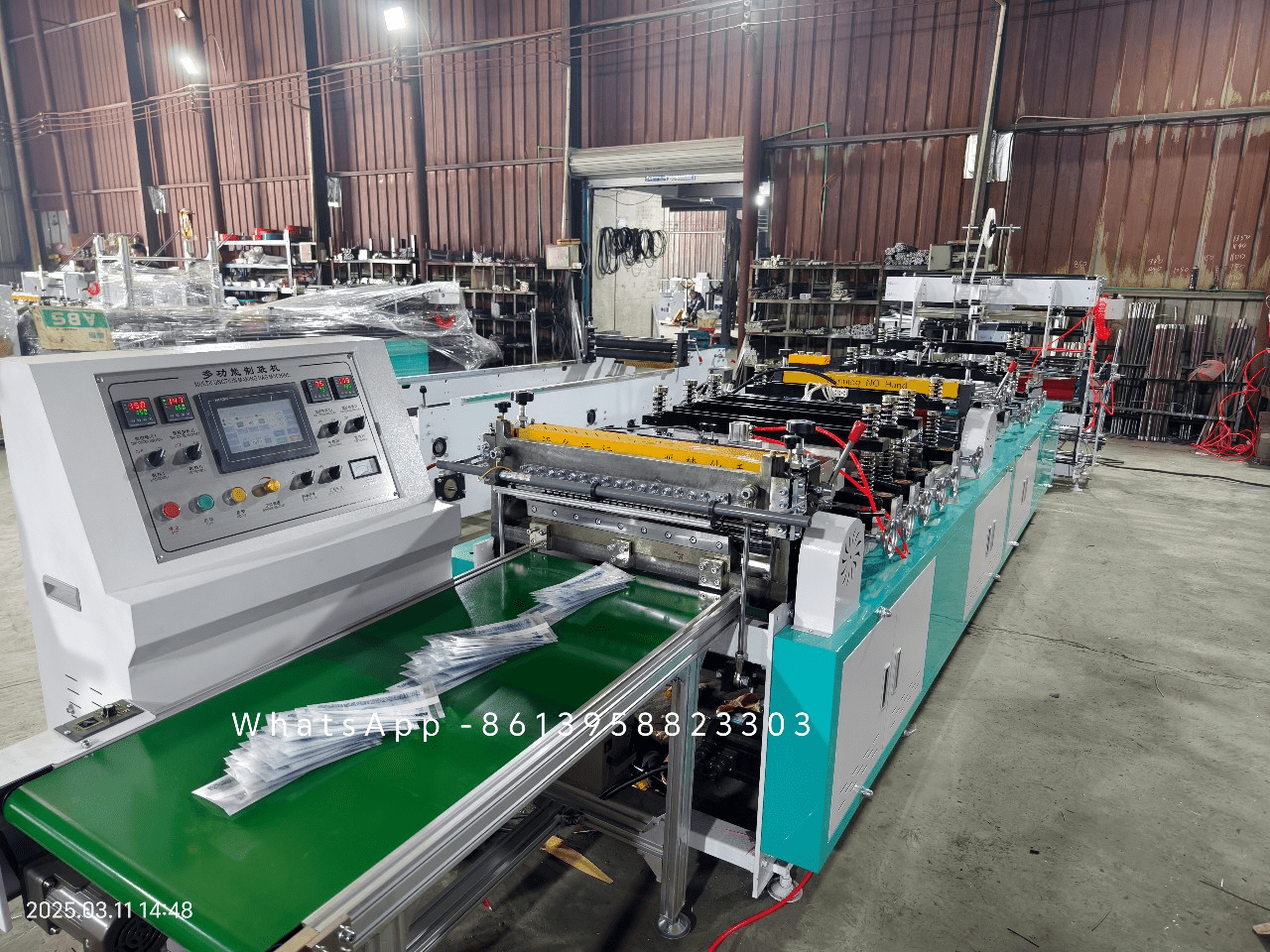

10. Dimensions: length 6.7 meters width 1.3 meters height 1.5 meters |

More machine pictures

|

|

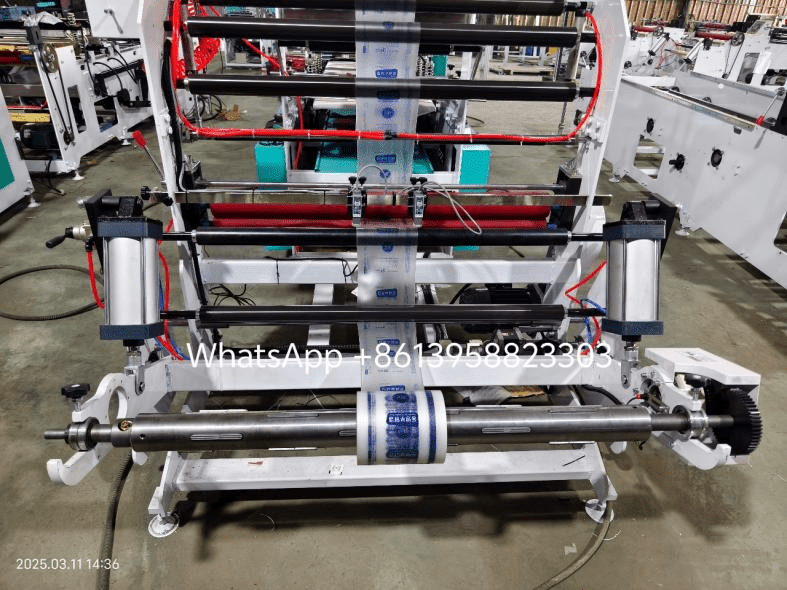

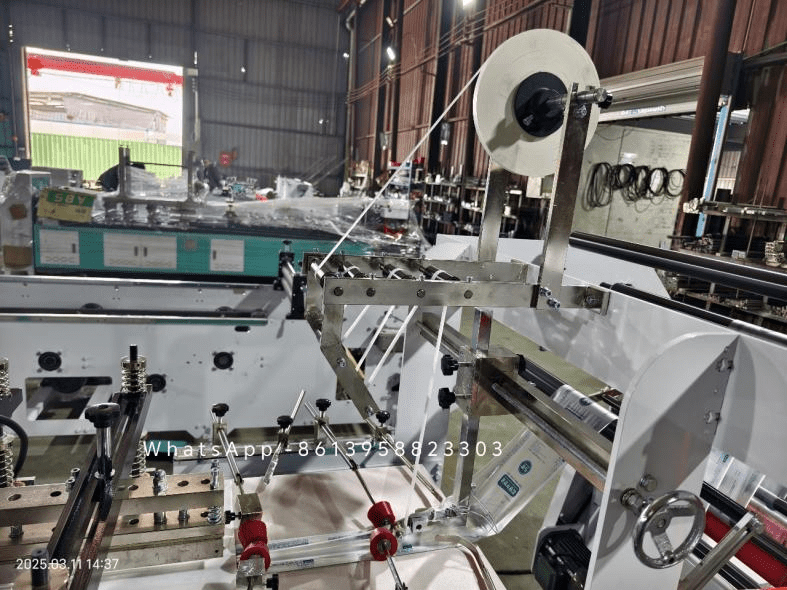

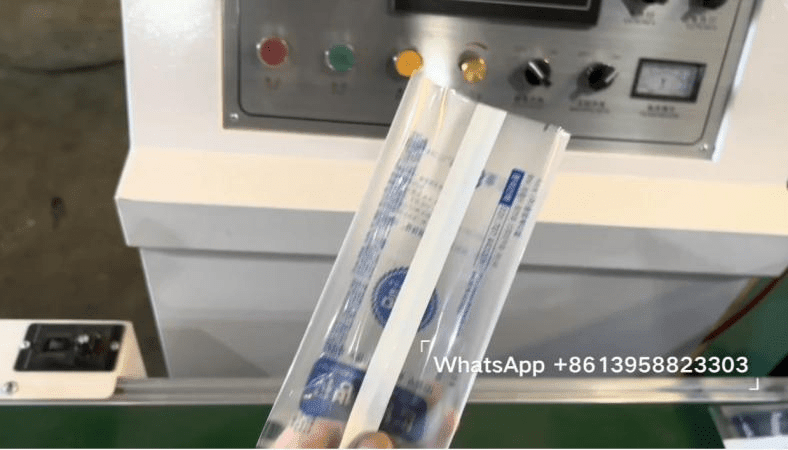

Unwinder with cylinder loading,with double photocell | Central paper strip |

|

|

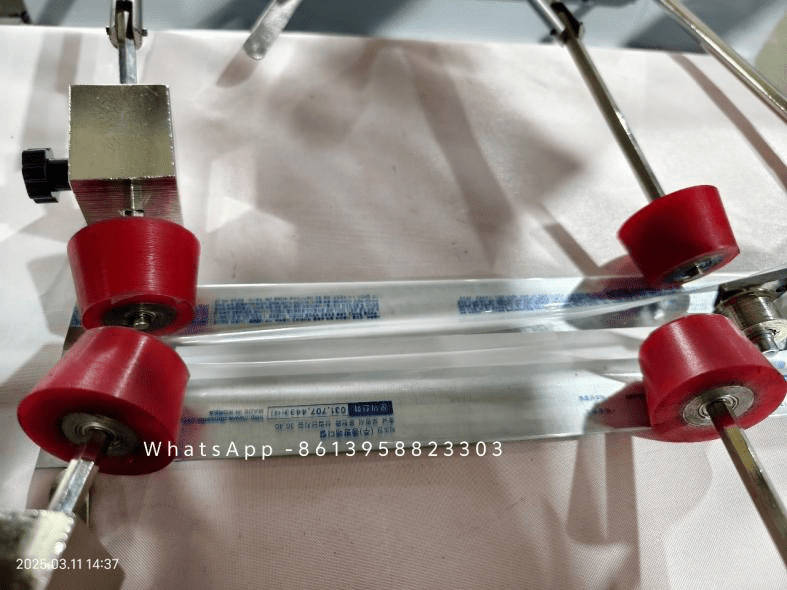

Bag forming | |

|

|

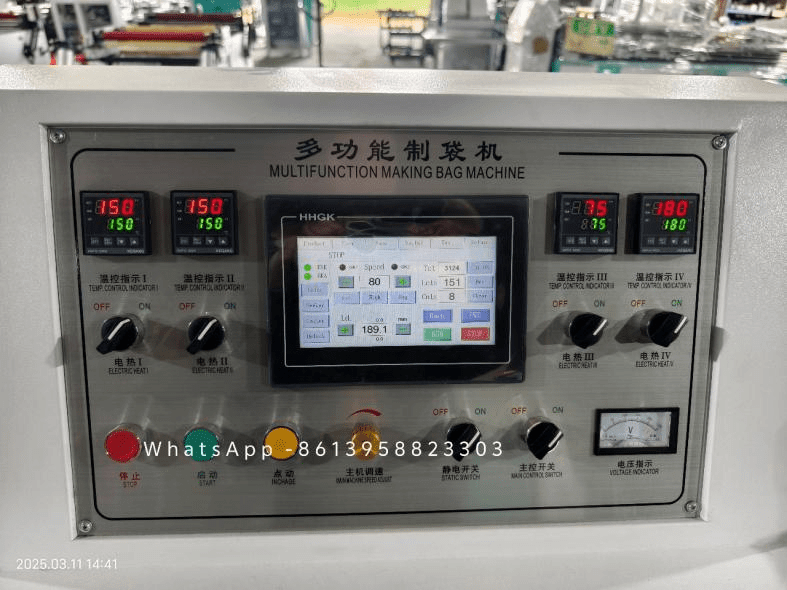

Computer control to set speed,batch | Photocell for tracking printed bag |

|

|

Bag comes out on conveyor belt | |

Bag Samples